1. Performance description:

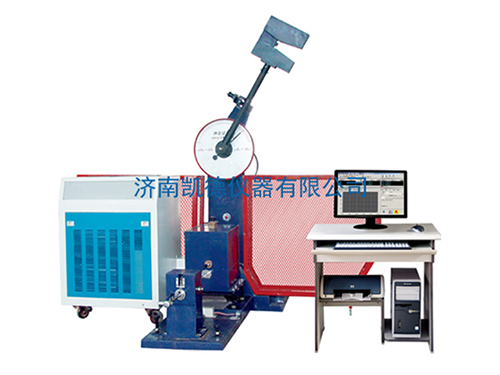

JBD Z W-300 B/500B microcomputer controlled automatic low temperature impact testing machine is used to test the impact resistance of metal materials under dynamic load. It is a necessary testing instrument for metallurgical machinery manufacturing and other units, and it is also a scientific research unit for new materials. Research indispensable test equipment. The aircraft from the instrument of impact testing machine and automatic cryogenic cooling means consisting automatic feeding positioning means for accurately testing, material analysis impact resistance at low temperatures. The low temperature device adopts cascade compressor for refrigeration, which has high reliability, good refrigeration effect, automatic temperature control, automatic alarm prompt, and the compressor is an imported brand machine. Pneumatic or electric feeding and positioning, fast speed and accurate positioning.

1. The machine adopts fully automatic control . The equipment for raising and hanging pendulum, feeding, positioning, impact and temperature adjustment are all electrical and mechanical control, equipped with a special feeding device for automatic feeding, and automatic section positioning of the sample. The time from the sample out of the furnace to the impact is no more than 2 seconds, which meets the requirements of the metal low-temperature Charpy impact test method. After impacting the sample, the remaining energy can be used to automatically raise the pendulum to prepare for the next test, with high work efficiency;

2. The main body of the JBD Z W-300 B/500B microcomputer-controlled automatic low-temperature impact testing machine is a split structure, a cantilever hanging pendulum, and a pendulum hammer body;

3. The impact knife is installed and fixed with screws, which is simple and convenient to replace;

4. Sample simply supported beam support;

5. The host is equipped with safety protection pins and a semi-closed safety protection net;

6. The testing machine found in line with GB / T229-2007 "metal material Charpy pendulum impact test method" GB / T3808-2002 "test Charpy impact test machine", GB4158-84 "metal Izod impact test method" of Impact test on metallic materials.

2. Main technical indicators of JBD Z W-300 B/500B microcomputer controlled automatic low temperature impact testing machine :

Serial number |

Project Description |

JBD Z W-300B |

JBD Z W-500B |

|

1 |

Operation method |

Microcomputer control |

||

2 |

Display method |

Computer display and printable |

||

3 |

Impact energy |

150/300J |

250/500J |

|

4 |

Distance from center of pendulum shaft to impact point |

750mm |

800mm |

|

5 |

Impact velocity |

5.2m/s |

5.4m/s |

|

6 |

Pendulum advance angle |

150° |

||

7 |

Specimen support span |

40+0.2mm |

||

8 |

Jaw fillet |

R1-1.5mm |

||

9 |

Impact blade fillet |

R2-2.5mm, R8±0.05mm |

||

10 |

Sample box capacity |

10 |

||

11 |

Cooling method |

Compressor refrigeration |

||

12 |

Low temperature range |

Room temperature to -40°C, -60°C, -80°C, -100°C (optional) |

||

13 |

Temperature control accuracy |

Fluctuation ±1.5°C, gradient 2°C |

||

14 |

Feeding speed |

≤2S |

||

15 |

Sample size |

10 (7.5, 5, 2.5) mm×10mm×55mm |

||

16 |

power supply |

AC three-phase 380V±10% 50Hz 5A; 220V |

||

17 |

Environmental conditions |

No corrosive medium around, no vibration, no strong electromagnetic field |

||