1. Equipment usage:

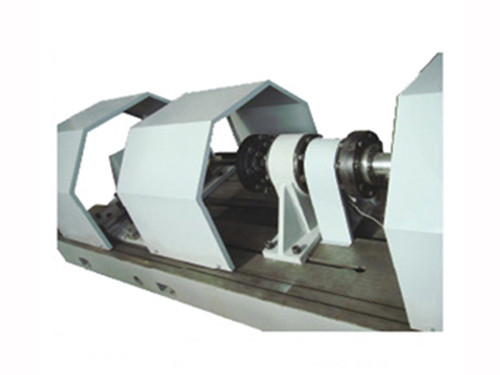

The test bench is automatically controlled by a computer and loaded by an imported servo motor, which meets the static torsional rigidity and static torsional strength tests of automobile half-shafts required by the "Automobile Drive Shaft Bench Test Method". Connect and install through corresponding fixtures, allowing the most

Within a large torque range, static torsion tests of various shaft parts, automobile rear axles, structural parts and various material samples can be carried out. It is an ideal high-performance test equipment for factories and mining enterprises, scientific research units, and universities. There are 5kNm, 10kNm, 20kNm, 30kNm,

50kNm, 60kNm, 80kNm are available.

2. Main technical indicators:

1. Maximum static torque: ±10kNm, the error of indication accuracy is not more than ±1%.

2. Output speed: 0-6r/min.

3. The maximum rotation angle of the loader: unlimited.

4. Rotation resolution: 1 minute.

5. Optical encoder specifications: 5000 lines/revolution.

6. Length adjustment range: 500-1500mm.

7. Control mode: torque control or angle control.

8. The system has protection functions such as overload and specimen fracture.

9. The computer screen displays the real-time values and related curves of various test parameters.

10. The printer prints test reports and curves.