1. Application of electro-hydraulic servo multifunctional long column structure test system:

WAW-F series computer-controlled multifunctional long-column structure test system is mainly used for concrete, super concrete, mortar, components, rocks, pipe piles, building materials, various metals, non-metals and composite materials, engineering plastics, wood, The tensile, compression, and bending tests and researches of cement and other specimens can also be used for the tensile, compression, and bending tests and researches of large components. It can perform compression, bending, and tensile tests of beams, columns, nodes, etc., and complete various structural tests (zero crossing points) such as repeated bending and low cycle cycles of beams, columns, nodes, etc. It can also complete the tensile and compressive tests of column specimens and repeated bending of beams. Add supporting test aids, which can also be used for jack testing; concrete beam vertical compression testing; metal pipe, seamless steel pipe, non-ferrous metal pipe flaring test, etc.

2. Features of electro-hydraulic servo multifunctional long column structure test system:

1. The precise automatic control and data acquisition system realizes the fully digital adjustment of the data acquisition and control process.

2. It has multiple control methods such as automatic load holding, stress and strain control, cycle control and self-programming control.

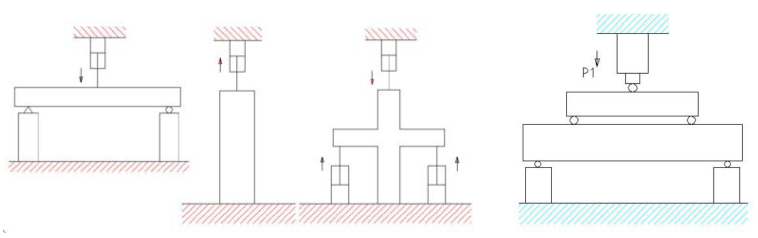

3. The four-column screw structure adopts a single rod and double-acting electro-hydraulic servo actuator on the top, which is used to apply test force, with high rigidity and good stability.

4. Servo measurement and control system realizes automatic loading at constant rate, maintaining constant test force, and cyclic loading and unloading.

5. According to GB, ISO, JIS, ASTM, DIN, BS and other national standards and international standards for testing and provide testing data.

6. Automatically complete the detection parameters such as the larger bearing capacity and strength of the material.

7. Servo measurement and control system, realizing automatic loading at constant rate, maintaining constant test force, cyclic loading and unloading.

8. Multiple protection functions: oil cylinder limit protection; hydraulic system overload and overflow protection; test force overload protection; overcurrent and overvoltage protection; safety protection when the sample is broken; operation prompt guide protection; automatic protection at the end of the test.

3. The main parameters of the electro-hydraulic servo multifunctional long column structure test system:

1. Maximum pressure test force: 2000kN; 3000kN; 5000kN; 10000kN; 20000kN

2. Test force measurement range: 2%-100% FS

3. Test force accuracy: ±1%

4. Force measuring method: oil pressure sensor measuring force

5. Maximum tensile test force: 30%FS.

6. Maximum bending test force: 20-40%FS.

7. Test force measurement range: 2%-100%FS

8. Test force accuracy: ±1%

9. Maximum stroke of actuator: 250mm

10. Displacement measurement method: built-in magnetostrictive displacement sensor measurement.

11. Displacement measurement resolution: 0.01mm

12. The maximum moving speed of the piston: ≤50mm/min

13. Test space: 2000mm; 3000mm, 4000mm, 5000mm, 6000mm, 7000mm, 8000mm (negotiable)

14. Maximum bending span: 2000mm-6000mm

15. When bending the maximum span, the maximum test force that can withstand: 1000-10000kN

16. Structure: Four-column structure, large curved base, single rod, double-acting electro-hydraulic servo actuator on top

17. Loading control mode: automatic control of cascade loading of any step length of displacement and test force.

18. Test aids: pressure plate, bending roller seat, T-shaped connecting bolt, etc.