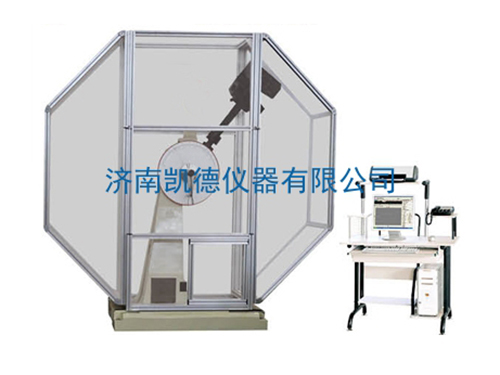

1. Overview of JB-300B/500B semi-automatic impact testing machine

1. Principle

JB-B series semi-automatic impact testing machine is a product developed in strict accordance with the national standard GB/T3808-2002 " Inspection of Pendulum Impact Testing Machine ", according to the national standard GB/ T229-2007 "Metal Charpy Notch Impact Test Method" carries out impact test on metal materials, and performs factory inspection according to JJG145-2007 "Pendulum Impact Tester". The cross-section of the style used is 10*10mm. It mainly tests ferrous metals with high impact toughness, especially steel and its alloys. The test principle is to use the difference between the front energy of the pendulum and the remaining energy after the impact to be displayed on the dial to obtain the absorbed energy of the tested sample.

2. Product features

It adopts semi-automatic control in operation, simple operation and high work efficiency. The remaining energy after the pendulum breaks the sample can be used to automatically raise the pendulum. When the impact test of the sample is continuously performed, its superiority can be more reflected .

3. Applicable industries

JB-B series are widely used in testing, scientific research and production in industries such as measurement, machinery manufacturing, metallurgy, pressure vessels, colleges and universities.

4. The main purpose

is to test ferrous metals with high impact toughness, especially steel and its alloys.

2. Technical characteristics of JB-300B/500B semi-automatic impact testing machine

1. The main body of the testing machine is of single-support column structure, cantilever type hanging pendulum, and the pendulum body is U-shaped;

2. The impact knife is installed and fixed with screws, which is simple and convenient to replace;

3. Sample simply supported beam support ;

4. The host is equipped with safety protection pins and equipped with safety protection nets;

5. The testing machine is semi-automatically controlled. Pendulum raising, hanging pendulum, impact and placement are all electrically controlled, and can use the remaining energy after breaking the sample to automatically raise the pendulum to prepare for the next test, especially suitable for continuous impact Test laboratories and metallurgical and machinery manufacturing departments that do a large number of impact tests;

6. The testing machine complies with the national standard GB/T3803-2002 "Inspection of Pendulum Impact Tester", and conducts impact tests on metal materials according to the national standard GB/T229-2007 "Metal Charpy Notch Impact Test Method". Ex-factory inspection according to JJG145-2007 "Pendulum Impact Tester".

3. Technical parameters of JB-300B/500B semi-automatic impact testing machine

|

Serial number |

Project Description |

Specifications |

||||

JB-300B |

JB-500B |

|||||

1 |

Impact energy |

300J (big pendulum) |

150J (small pendulum) |

500J (big pendulum) |

250J (small pendulum) |

|

2 |

Scale range and division value |

Energy range |

0-300J |

0-150J |

0-500J |

0-250J |

Division value per small grid |

2J |

1J |

5J |

2.5J |

||

3 |

Pendulum moment and impact energy |

Pendulum impact energy |

300J |

150J |

500J |

250J |

Pendulum moment |

160.7695Nm |

80.3848Nm |

267.9492Nm |

133.9746Nm |

||

4 |

Pendulum advance angle |

150° |

150° |

|||

5 |

Distance from pendulum center to impact point (test center) |

750mm |

850mm |

|||

6 |

Impact velocity |

5.2m/s |

5.4m/s |

|||

7 |

Specimen support span |

40mm |

40mm |

|||

8 |

Arc radius at the end of specimen support |

1 ~1.5mm |

1 ~1.5mm |

|||

9 |

Inclination angle of support surface of specimen support |

0° |

0° |

|||

10 |

Impact knife arc radius |

2~2.5mm |

2~2.5mm |

|||

11 |

The angle between the two slopes of the impact knife |

30° |

30° |

|||

12 |

Impact blade thickness |

16mm |

16mm |

|||

13 |

Specimen specifications |

10×10×55mm |

10×10×55mm |

|||

14 |

Test machine weight |

≈450kg |

≈550kg |

|||

15 |

External dimensions of testing machine |

2124×600×1340mm |

2300×600×1400mm |

|||

16 |

Power supply (three-phase four-wire system) |

50Hz, 380V, 250W (main motor) |

50Hz, 380V, 250W (main motor) |

|||