1. Main functions:

1. TPW -300 type electro-hydraulic servo leaf spring fatigue test is mainly used to test the dynamic and static mechanical properties of various steel pole springs. It can not only complete the leaf spring fatigue test required by the standard, but also perform the characteristic test before the fatigue test. Such as automatic drawing of test force_deformation curve, calculation of leaf spring stiffness, etc. By replacing accessories, you can also test the dynamic and static mechanical properties of other parts by hand, which has the characteristics of good professionalism, high reliability, advanced technology, and easy-to-hand upgrade.

2. Meet GB/T19844-2005 "Leaf Spring", JB3383-1998 "Automobile Leaf Spring Bench Test Method" and QCn 29035-1991 "Automobile Leaf Spring Technical Conditions" JBT 7283-2001 "Agricultural Machinery Leaf Spring" ISO18137-2015 "Leaf Spring-Technical Specifications" and other national industry standards.

3. It can complete the static and dynamic mechanical performance test of the leaf spring

1) Deformation test under vertical load

2) Leaf spring characteristic test: automatically draw test force-deformation and calculate leaf spring stiffness.

3) Dynamic mechanical performance test of leaf spring.

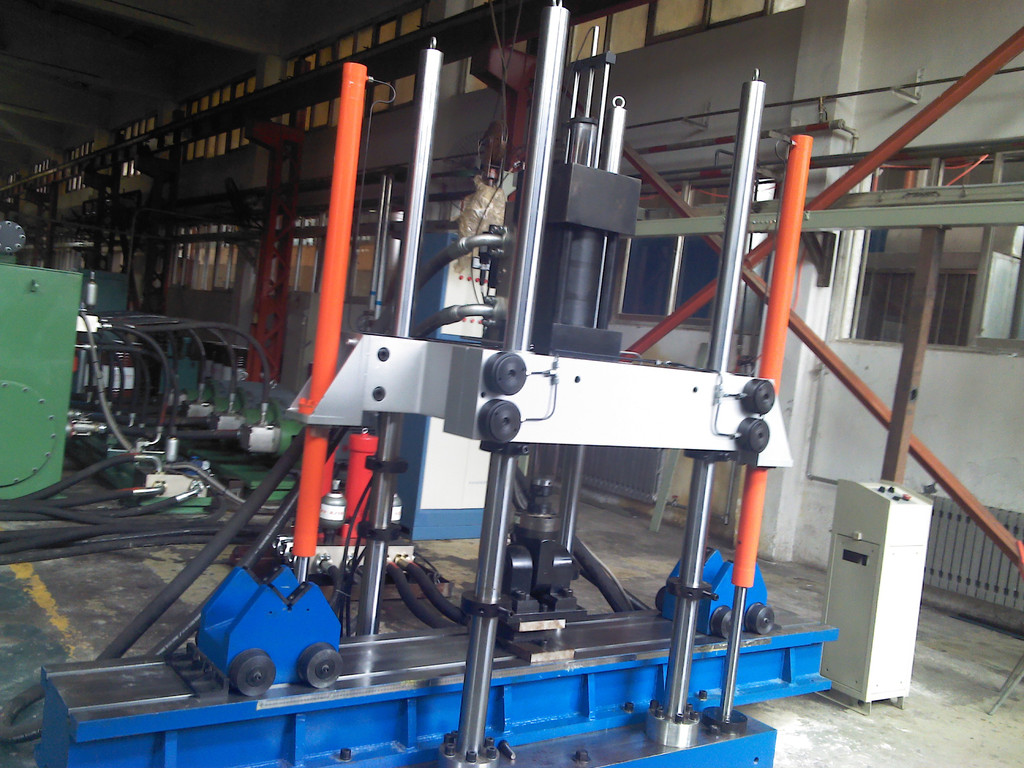

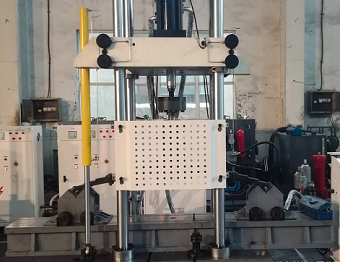

2. Main technical indicators:

1. Maximum dynamic and static test force: ±300KN;

2. Maximum static test force: ±300kN, measurement range: 2%-100%FS.; indication accuracy from 20% ±1%FS;

3. Maximum dynamic test force: ±300kN, measurement range: 2%-100%FS; display accuracy: ±1%, amplitude fluctuation not greater than ±1%FS;

4. The maximum stroke of the actuator: ±150mm (total stroke 300mm), with an indication accuracy of ±1%FS from 20%;

5. Frequency range: 0.1-15Hz;

6. Control mode: closed-loop control of force and displacement;

7. Main input test waveforms: sine wave, square wave, triangle wave, static test ramp wave, etc.;

8. With overload, break protection, automatic shutdown after the test, etc.;

9. Servo pump station: 220L/min, 280L/min, 360L/min, 700L/min, etc., pressure 21Mpa;

10. Effective test space: height 1000mm, distance between columns ≥580mm×750mm;

11. Test space adjustment method: hydraulic lifting/locking moving beam;